Cybrid Encyclopedia - In 2018, the "hetero-knot" suddenly went up in flames....

Published on.

2022-11-25 13:40

In 2018, "heterojunction" suddenly caught fire: on May 25, Rainbow Group invested 2GW of high-efficiency heterojunction cell projects; on July 28, Akcome Group announced a total investment of 10.6 billion in heterojunction high-efficiency solar cell projects to start construction; Jin Energy, which has been plowing into heterojunction for years, announced at the CSPV conference in November that its H super The highest efficiency of high-efficiency heterojunction cell mass production broke through to 24.04% and predicted that the gap between the overall cost of heterojunction and monocrystalline PERC would narrow to 20% by the end of 2018; on November 18, the third phase of Tongwei Solar's project went into operation and 1GW of ultra-high efficiency heterojunction cells started.

In this way, it seems that the heterojunction is progressing towards the path of mass production and dissemination.

Why is the Hetero-Knot so hot all of a sudden?

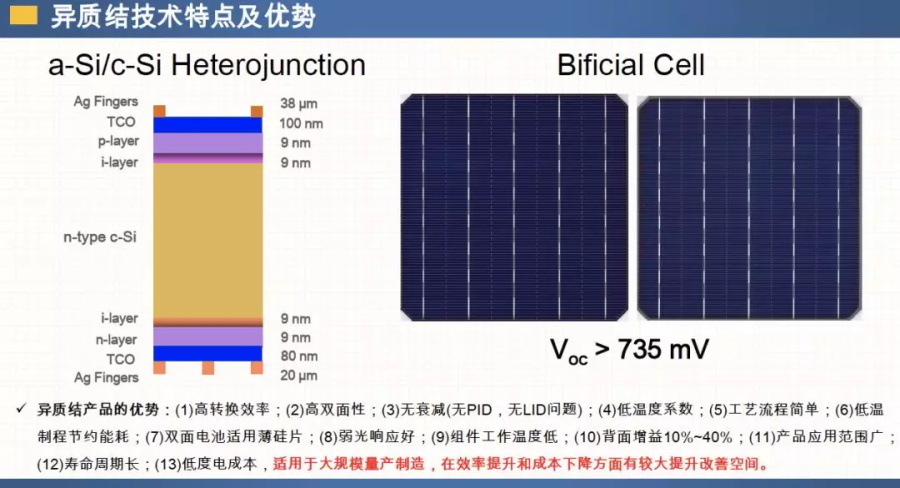

The various advantages of heterojunctions have been presented by experts in several heterojunction forums.

Heterojunction has so many advantages, it is inevitable that the industry is now "hot" for heterojunction "for granted". However, the concept of heterojunction is not new to us, as early as 1990, the Japanese company Sanyo successfully developed and trademarked the intrinsically thin heterojunction (HIT) for the first time, with a cell efficiency of 18.1% at that time. 2010, Sanyo announced the expansion of HIT module production; in 2012, it was acquired by Panasonic, and in February 2013, Sanyo's HIT conversion efficiency reached a maximum of 18.1%. 24.7%.

The question arises: if heterojunction batteries are so efficient, then why did it take 28 years for heterojunctions to become so "hot" today?

Cost is the biggest disadvantage of heterojunction

According to experts, heterojunction has not been able to get industry mass production applications, a big reason is the high cost.

In 1990, Sanyo successfully developed the heterojunction cell (and named HIT), domestic Junshi, saion, etc. also try to promote heterojunction after 2010.

Although the efficiency of heterojunction cells is much higher than the conventional crystalline silicon route, heterojunction still hastwo thresholds in production cost that cannot be overcome!

1.Heterojunction cell production equipment is completely incompatible with the conventional crystalline silicon cell route. In recent years, PERC, black silicon, IBC and other new battery technologies continue to push up the battery photoelectric efficiency, but these new technologies are superimposed on the traditional crystalline silicon battery technology, enterprises can transform the existing battery production line to achieve the mass production of new technologies. The heterojunction cell process is very different, it can not use the existing production line, can only invest in a new production line of their own equipment, the initial advanced equipment are basically monopolized by foreign enterprises, the price is expensive. For enterprises with shortage of funds, it is always a choice whether to go on or not, especially when the heterojunction has not been applied on a large scale and has not been proven outdoors.

2. Heterojunction batteries have high efficiency, large initial investment and high production cost, which need to be reflected by the advantage of electricity cost. The high double-sided consistency of heterojunction batteries is an important way to reduce the cost of energy consumption. However, to achieve double-sided cell power generation, the production capacity of double-sided modules must be matched. Although heterojunction cells were ready for production in 2010, it is well known that double-sided double-glass modules were still a special-need product at that time. The qualification rate of double-glass modules was less than 50%, the glass selection was 3.2mm and above, the modules were heavy, and the cells were mostly manually soldered. It can be said that the heterojunction of five years ago had the efficiency of power generation, but not the capacity for mass production.

Double-glass double-sided, unintentionally poke a stick in the wood.

Double-sided glass has become a heterogeneous junction cell show the cost advantage of electricity can not get around the "knot". This knot, but by the PV people inadvertently untie.

Around 2012, industry leaders such as Suntech, Trina, in order to solve the module PID effect, the aging life of the backsheet materials began to study the alternative route of double glass to the backsheet. After several years of efforts by the whole industry chain, including modules, glass, packaging materials and junction boxes, the qualification rate of double-glass modules can gradually be compared with single-glass, the production cost is basically equal, the thickness of glass is reduced to 2.5mm, 2mm, (Armatron is developing 1.6mm ultra-thin glass), and the split junction box makes the module system more efficient. Surface photovoltaics and power plants in harsh weather conditions have driven the evidence for double-glass modules. In just a few years, the market share of double-glass modules increased from zero to around 7% by the end of 2017.

(原文链接:【独家】双玻调研:上半年度双玻产量惊人!双玻逆势大爆发)

Inadvertently poke a stick in the mud and it will grow into a shade. The breakthrough in the double-glass module process has untied the "knot" in the mass production of double-sided heterojunction modules, giving heterojunction specialists hope for cost reduction.

Also in the past few years, the industry's technology has advanced by leaps and bounds, making it easier to achieve double-sided heterojunction technology. This includes bifacial cell technology, automatic string welding technology, and advances in the localization of equipment and auxiliary materials. As a result, from 2015 onwards, more companies have become bullish on the efficient technology of heterojunction, with Jineng, Zhongzhi, GCL and Aixu increasing their R&D and investment in heterojunction technology.

The "Leaders" program, a springtime for the development of heterojunction technology

"Heterogeneous knot" and "double glass" hand in hand behind the success, there is a "mystery guest" to help. Because even if the heterogeneous knot double-sided double glass has been able to achieve a relatively low cost of electricity, but the heterogeneous knot is still very high unit price. Why can heterojunction still get the favor of the industry?

In 2015, a mystery guest "pink" debuted, it is the "PV Leader Program".

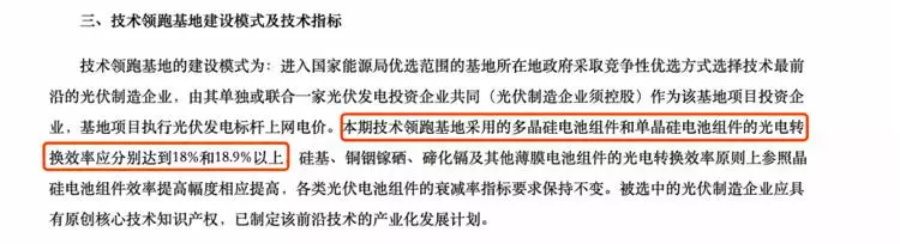

Since the country's push for a PV "leader program" in 2015, we have seen an increasingly clear policy direction, from past subsidies for PV projects, to the full implementation of subsidies for kWh, to special support for high-efficiency cells and modules. In particular, the increase in the leader certification index from 2017 onwards and the introduction of application leader and technology leader bases in the country have further guided the industry's development of high-efficiency modules and driven the overall module efficiency of the industry.

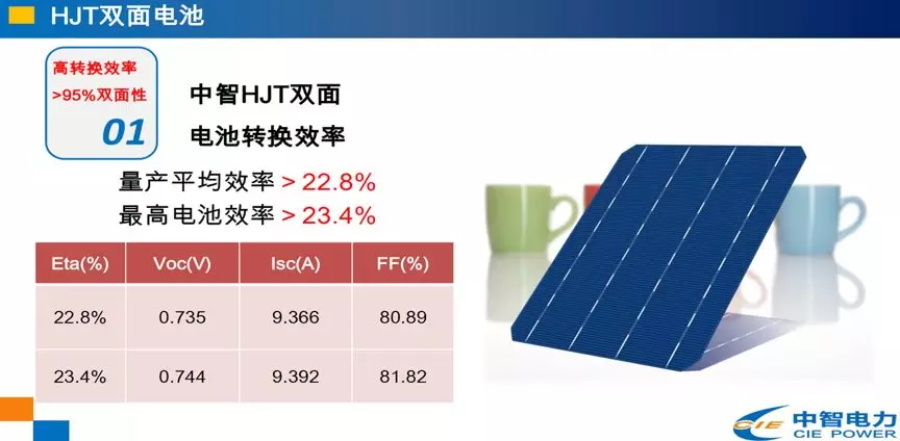

The requirements of the leader demonstration base for high-efficiency technology and the requirements for the cost of electricity, so that the industry no longer only looks at the unit price and initial investment, but also focuses on the long-term investment benefits and optimistic about future technology. Heterojunction two-sided consistency, >95% double-sided, mass production average efficiency of >22.8%, the highest cell efficiency of >23.4%, fully meet the requirements of the "leader", the market also needs more double-glass double-sided!

In this context, heterojunction batteries have accelerated the pace of industrial application.In 2018, Rainbow Group, Aikang Group and Tongwei Group have invested tens of billions of yuan to carry out the production of heterojunction batteries.

Heterojunction technology exchange heats up, HAC conference successful

Heterojunction technology is a hotspot of industry interest.

The first international forum on heterojunction exchange, held by the Institute of Microsystems, CAS, on 25 October 2018.

The 14th CSPV was held in Xi'an on November 8-10, and for the first time, heterojunction batteries became a hotspot of the conference in the form of thematic sub-forums.

On November 18, Nanchang University held the HAC forum on the development and localization of heterojunction PV. In the HAC forum, Prof. Wang Wenjing from the Institute of Electrical Engineering, Chinese Academy of Sciences, and Mr. Xu Xin from CIIC (Taixing) discussed the heterojunction products in detail from the characteristics/advantages of heterojunction technology, technology development route, and market outlook.

The gain in power generation of double-sided modules is closely related to the actual application scenario. In addition, the absorption light source on the back side can be increased by raising the height of the module and increasing the tilt angle of the module, thus increasing the power generation gain on the back side.

Contact Us

China Headquarters: No. 369 Yegang Road Wujiang Economic& Development Zone. Suzhou,China.215200

E_mail:sz-cybrid@cybrid.net.cn

Copyright © 2022 Cybrid Technologies Inc. All Rights Reserved. Powered by 300.cn