The MoPro® overall solutions can prolong the service life of PV power station for 10 years

Module + Prolonglife = MoPro®

Use MoPro® to improve efficiency and gain for PV power station

The service life of the existing PV power station is longer than 25 years.

In the whole life cycle of the power station, due to improper material selection of the power station system and negligence of the operation and maintenance personnel, the power station is prone to problems such as scratching/cracking of the backsheet of single glass module, water seepage of the frame of single glass module, delamination of the double glass module, connector cracking, wire and cable cracking, and dirt on module glass.

At this point, diagnosis of the power station system and recommendation of the overall solution become imminent. Appropriate materials and measures can prolong the reasonable service life of the power station by 60% to about 40 years*, greatly improving the service life, energy output and overall gain.

* Power stations may vary with different basic conditions.

8 Problems of failure of PV power station

Other Solutions

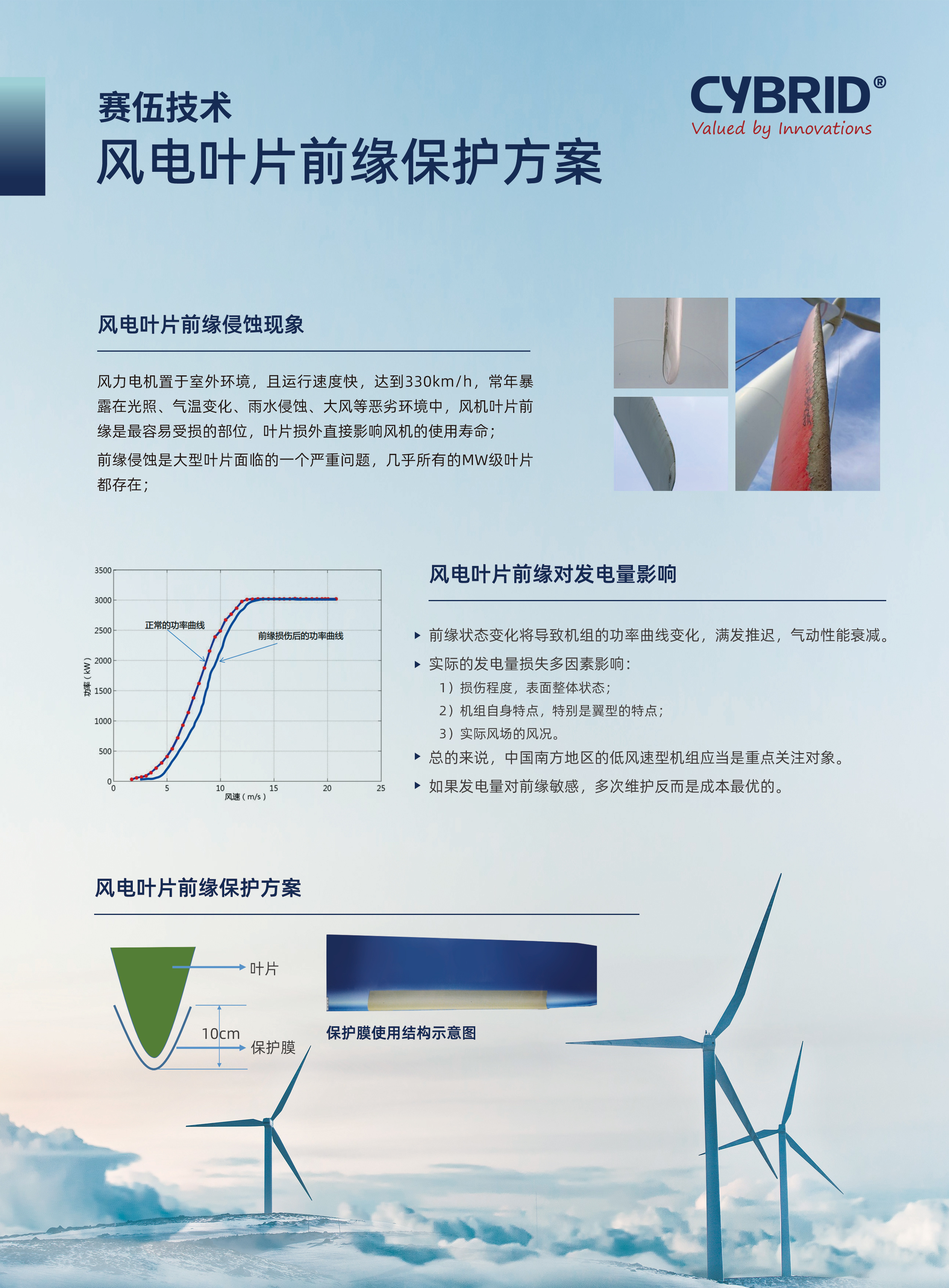

Wind power blade leading edge protection solutions

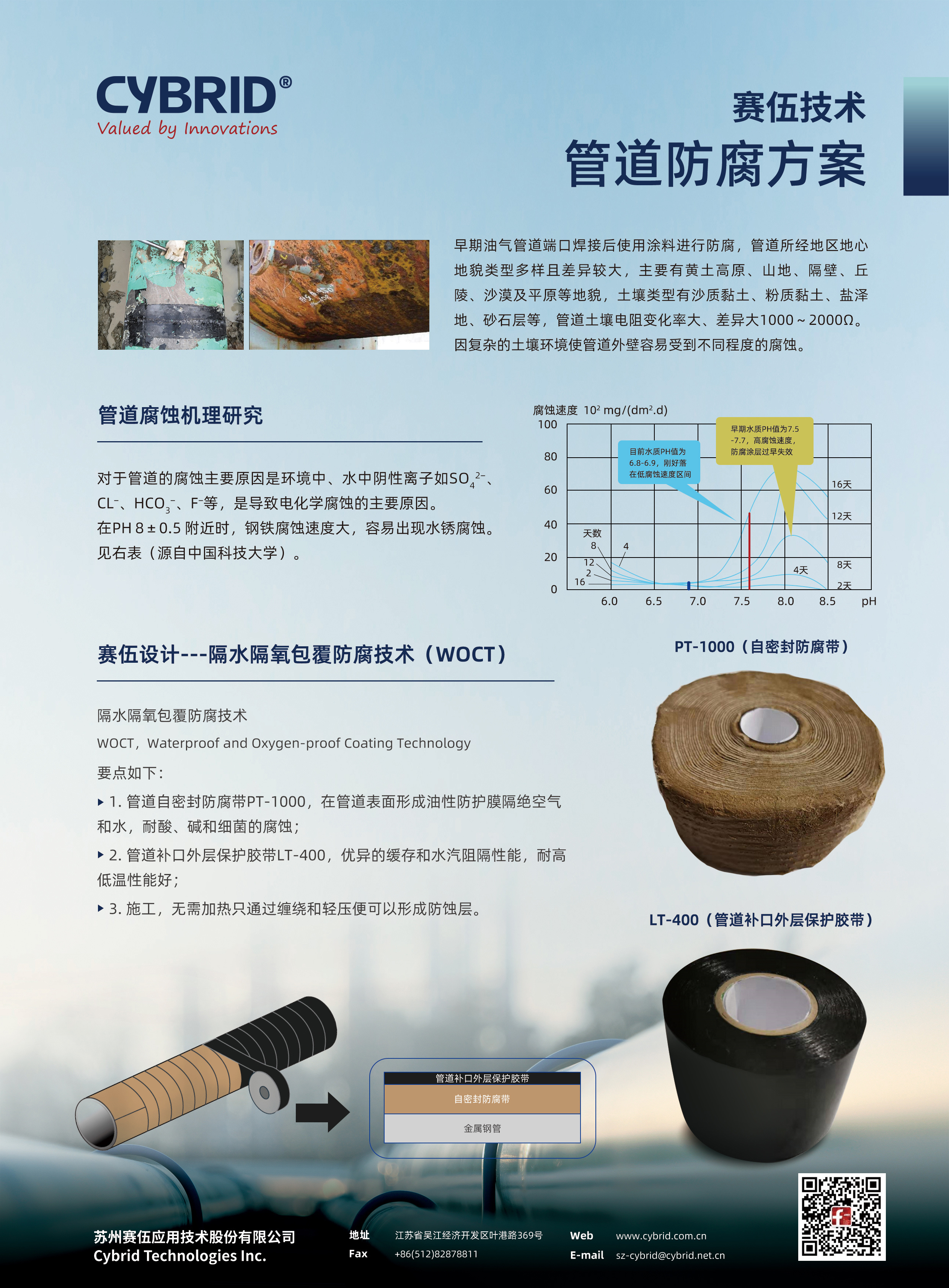

Pipeline anti-corrosion solutions

Contact Us

China Headquarters: No. 369 Yegang Road Wujiang Economic& Development Zone. Suzhou,China.215200

E_mail:sz-cybrid@cybrid.net.cn

Copyright © 2022 Cybrid Technologies Inc. All Rights Reserved. Powered by 300.cn